√無料でダウンロード! aluminum 6061 chemical composition 230350-Al 6061 t6 material chemical composition

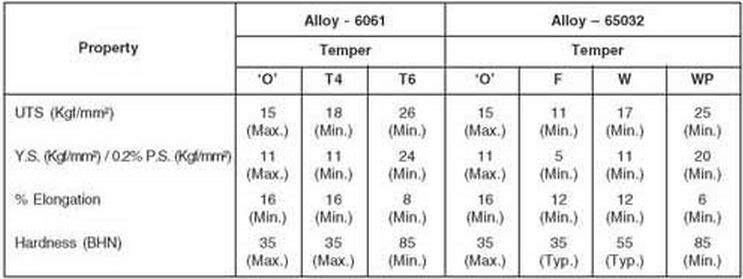

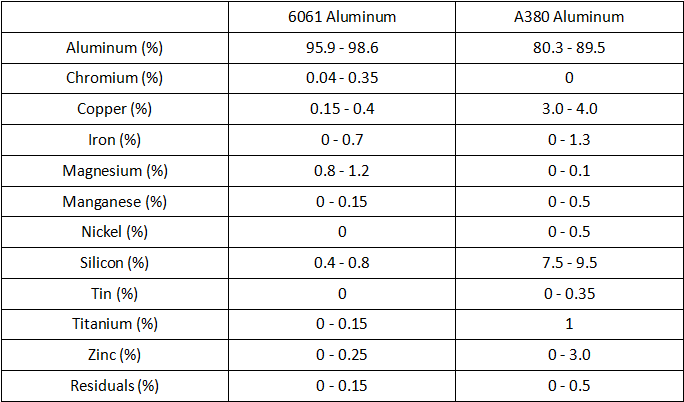

Element Percent by Weight;ENAWAlMg1SiCu (ENAW6061) Aluminium 6000 series (Magnesium Mg and Silicon Si are major alloying elements)0721 · 6061 aluminum alloy is a great general purpose alloy, and is used in all kinds of applications ranging from electronics to welded assemblies This is a consequence of its good formability, weldability, fair corrosion resistance, and moderately high strength, which all make 6061 aluminum highly versatile The density of type 6061 aluminum is 27

Aluminium Alloy 6061 Aluminium Guide Com

Al 6061 t6 material chemical composition

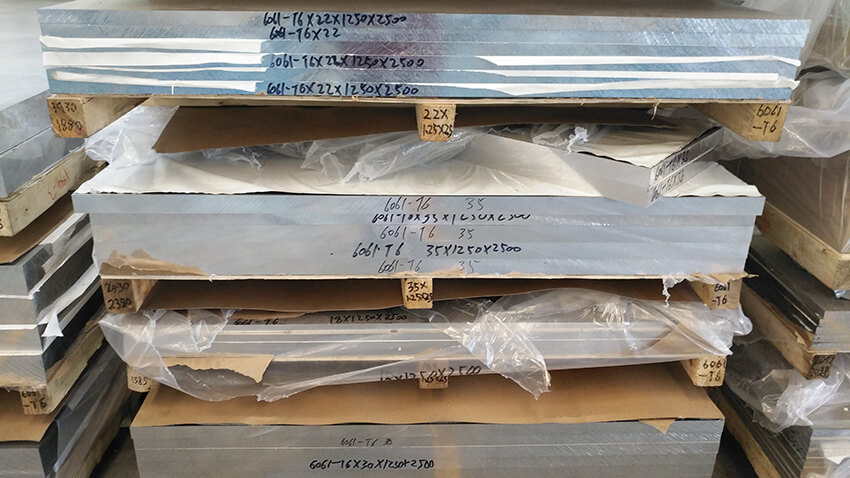

Al 6061 t6 material chemical composition-Stock Size Range of 6061 Aluminum Pipe NPS 1/4″ through 12″ Schedules 10, 40, 80;Aluminum 6061 composition If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, we will contact you within one business day

6061 Aluminum Alloy Chemical Composition Download Table

6061 aluminum sheet is a heattreated and strengthenable aluminum alloy sheet with medium strength It belongs to 6000 series (AlMgSi) alloy aluminum sheet and has good weldability At the same time, 6061 aluminum coil sheet has excellent aluminummagnesium composition ratio and strong corrosion resistanceEN AW6061 AlMg1SiCu Type High strength structural alloy Nedal Aluminium Alloy data sheet jun05 POBox EN AW6061 NL3500 GA Utrecht, The Netherlands rev00 T 31 30 F 31 30 sales@nedalnl wwwnedalcom The alloy EN AW6061 is a high strength alloy for highly loaded structural · Chemical Composition The following table shows the chemical composition of the aluminum 6060 alloy Element Content (%) Aluminum, Al 978

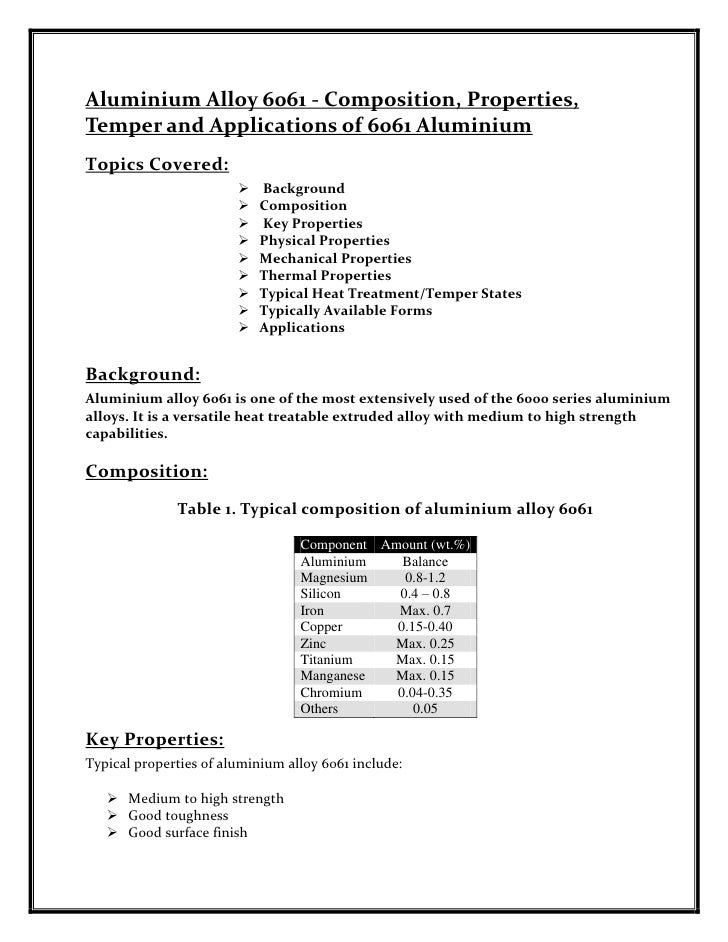

Specifications of 6061 Aluminum Pipe ASTM B 221 ASTM B241, ASTM B429, AMSQQ00/8, MILDTL Type A;6061 aluminum properties include its structural strength and toughness, its good surface finish, its good corrosion resistance to atmosphere and sea water, its machinability, and its ability to be easily welded and joined Most other aluminum alloys are difficult to weld due to their chemical composition and lack of conductivityThe most economical of the heattreatable aluminium Chemical Composition of Aluminium 6061 Table1 Chemical Composition of Aluminium 6061 alloy Manganese (Mn) 015% Iron (Fe) 070% Copper (Cu) 015 040%

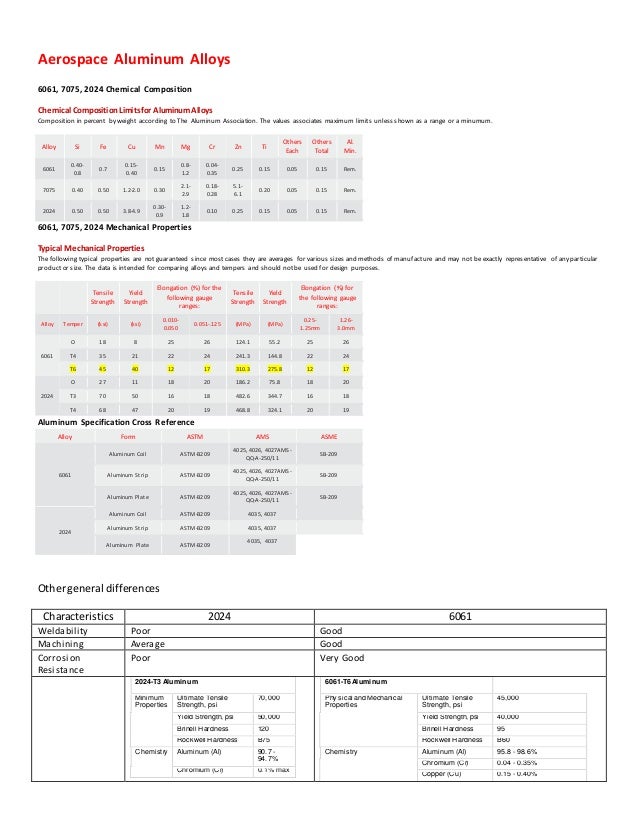

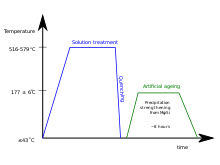

6061 Aluminum Specification 6061 Chemical Composition %It is one of the most common alloys of aluminium for general purpose use It is commonly available in pretempered grades such as, 6061O (solutionized), 6061T6 (solutionized and artificially aged), 6061T651 (equivalent to T6 in rolled stock) Basic properties 6061 has a density of 270 g/cm³ ( lb/in³) Chemical composition95 HB Aluminium alloy 6061 is a medium to high strength heattreatable alloy with a strength higher than 6005A It has very good corrosion resistance and very good weldability although reduced strength in the weld zone It has medium fatigue strength It has good cold formability in the temper T4, but limited formability in T6 temper

Chemical Composition Of 6061 T6 Al Alloy Download Table

Chemical Composition Of Al 6061 Alloy Download Table

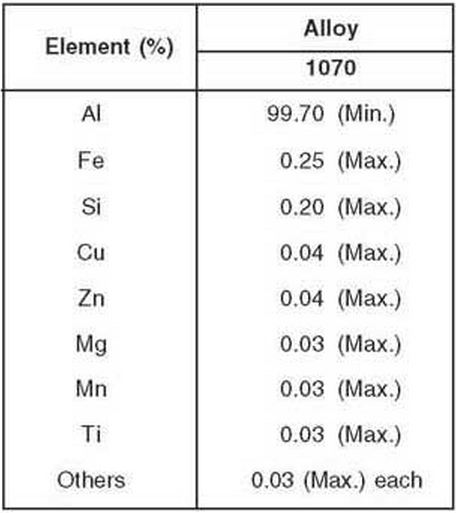

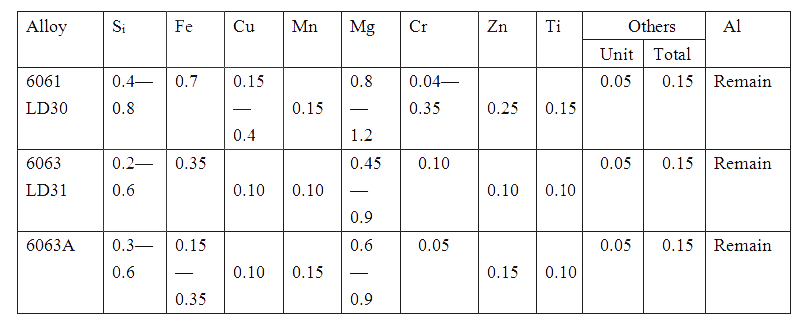

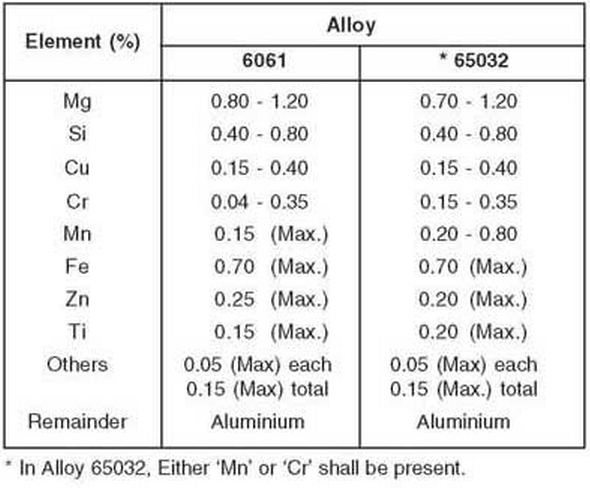

· 6061 and 60 aluminum alloy are the alloy in the aluminummagnesiumsilicon family (6xxx series) The main difference is that the composition ratios of silicon and magnesium in 60 and 6061 are different But no matter chemical composition or performance, alloy 6061 and 60 are very similar, and we think they are instead able2405 · 6061 Aluminum Alloy (Al 6061T6, 6061T651, 6061T4) AL6061 aluminum alloy is a general purpose structural alloy developed by Alcoa in 1935 The temper designations mainly have 6061T4, T451, AL 6061T6, 6061T651, etc It is one of the most widely used alloys The main alloying elements are magnesium (Mg) and silicon (Si)Aluminum 6061 was chosen because 6061 Aluminium shows good formability, weldability, high corrosion resistance;

Aluminium Alloy Wikipedia

Comparative Investigation Of Friction Stir Welding And Fusion Welding Of 6061 T6 50 O Aluminum Alloy Based On Mechanical Properties And Microstructure Topic Of Research Paper In Materials Engineering Download

Si Silicon 040 080% Fe Iron 070% max Cu Copper 015 040% Mn Manganese 08 12% Mg Magnesium 08 12% Cr Chromium 025% max Zn Zinc 025% max Ti Titanium 015% maxOthers Each 005% maxOthers Total 015% max Al Aluminum Balance7075 vs 6061 aluminum chemical composition 7075 aluminum comes from the 7xxx series, while 6061 aluminum from the 6xxx series of aluminum alloys grade With that in mind, it is notable that 6061 aluminum has a higher concentration of silicon, while 7075 aluminum · 7075 aluminum alloy is part of the 7xxx series, where zinc and copper are used as the primary alloying elements 6061 aluminum is part of the 6xxx class of aluminum, which use magnesium and silicon as their primary alloying elements Here is a full breakdown of 7075 aluminum vs 6061's chemical composition

Aluminium Alloy 6061

What To Know About 6061 Aluminum Kloeckner Metals Corporation

6061 Aluminum plate is a precipitationhardened aluminum alloy containing magnesium and silicon as its major alloying elements 6061 aluminum plate is one of the most versatile of the heattreatable alloys 6061 is popular for its medium to high strength requirements, good toughness and excellent corrosion resistance6061 aluminum properties include its structural strength and toughness, its good surface finish, its good corrosion resistance to atmosphere and sea water, its machinability, and its ability to be easily welded and joined Most other aluminum alloys are difficult to weld due to their chemical composition and lack of conductivity6060 aluminium alloy is an alloy in the wrought aluminiummagnesiumsilicon family (6000 or 6xxx series) It is much more closely related to the alloy 6063 than to 6061The main difference between 6060 and 6063 is that 6063 has a slightly higher magnesium content

Scielo Brasil Solution Treatment Behaviors Of 6061 Aluminum Alloy Prepared By Powder Thixoforming Solution Treatment Behaviors Of 6061 Aluminum Alloy Prepared By Powder Thixoforming

Chemical Composition And Properties Of Aluminum Alloys United Aluminum

· Alloy Series and Chemical Composition The first difference between 6061 and 7075 can be found right away just by looking at their number designations 6061 is in the 6XXX series of aluminum alloy grades and 7075 is in the 7XXX series Knowing this, without even digging into their individual material data sheets, it can be deduced that 60611506 · From the chemical composition, it can be seen that the main difference is that the composition ratio of the silicon magnesium of marine grade aluminum 6061 and 60 is different Marine grade aluminum 6061 and 60 about characteristics 1 The quench sensitivity of 60 aluminium sheet is higher (compared to 6061 aluminum sheet)6061 Aluminum Alloy Properties General Characteristics Characteristic Appraisal Strength Medium to High Corrosion Resistance Good Weldability & Brazability Good Workability Good Machinability Good Chemical Composition Element Minimum % Maximum % Magnesium 08 12 Silicon 04 08 Iron No Min 07 Copper 015 04 Manganese No Min 015

Aluminium Alloys And Production

Aerospace Aluminum Alloys

Grade 6061 aluminium is a medium strength aluminium alloy that is predominantly produced for the American market Grade 60 is the nearest equivalent grade that is readily available in the UK In fact, differences between grade 6061 and 60 are very slight indeed – they have over 99% of their composition in common, and therefore in the vast · June 28, 17 Aluminum Machinery Total Solution Provider Blog 6063 and 6061 Chemical composition 6063 and 6061 Chemical composition Alloy's No Chemical composition (%) Si Mg Cu Fe Mn Ti Cr Zn Other impurity single total 6063 02~06 045~09 010 035 010 010 010 010 005 015 6061 04~08 08~12 015~04 070 015 015 015 0ALLOY 6061 is a precipitation hardening alloy, containing magnesium and silicon as its major alloying elements More specifications from United Aluminum PHONE

Aluminum 6061 T6 Price For Truck Manufacturing Aluminium Price Per Kg Buy Aluminum 6061 T6 Price Aluminium Price Per Kg Product On Alibaba Com

Aluminium Alloy 6061 Aluminium 6061 He Aluminium 6061 He Sheets Plates

· AA 6063T5 is also an aluminium alloy having the same alloying elements of magnesium and silicon So the to find the key difference between the two, we must first take a look at the chemical composition of both The Chemical Composition for 6061T6 is as follows Magnesium minimum 08%, maximum 12%;6061 Aluminum Get to Know its Properties and Uses Gabrian Chemical Composition of 6061 Aluminum This alloy is part of the 6000 series of alloys As such, its major alloying elements are magnesium and silicon Magnesium is added to increase strength, while the silicon is added to reduce the metal's melting temperatureAluminum 6061 chemical composition If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, we will contact you within one business day

6061 Aluminum Alloy Chemical Composition Download Table

1

Chemical Composition of AISI 6061 Al Aluminum Alloys UNS ID 6061 6061 Al Aluminum Alloys consists of Silicon (04% 08%), Magnesium (08% 12%), Aluminum (Bal) as · 6063 and 6061 Chemical composition Not only aluminium dross processing machine, dross cooling machine, but also dross ball mill and sieving machine Aluminum extrusion auxiliary equipment can be offered here, such as aluminum extrusion shape corrector, aluminum profile wrapping machine, aluminum profile polishing machine and wood grain effect2710 · The Aluminum 6061 is made up 958 to 986% aluminum, with 08 to 12% magnesium, and 04 to 08% Silicon Besides, it contains a trace number of elements including Copper, Chromium, and more 7075 Aluminum Grade The alloy – 7075 aluminum was first developed secretly by a Japanese company in 1936

Aluminum Alloy 6061 Information And Specifications

What Is 24 Aluminum Aluminum 24 Properties Difference Between Al 6061 And 24

Equivalents of AA 6061 UNS 6061, Aluminium 6061, AA6061, Al6061 Standard ASTM B9, EN573, EN485 Specification ASTM B9 – This specification covers aluminum and aluminum alloy flat sheet, coiled sheet, and plate in various alloys BS EN 573 – This specification covers aluminium and aluminium alloys – Chemical composition and formChemical Properties of 6061 Aluminum Plate;Here you can view Aluminum Alloy Specifications, mechanical properties of aluminium alloys (aluminum alloy properties table), Chemical Composition We also Manufacturer & Supplier of alloy products for your specific requirements

Aluminum Profiles With Alloy 6061 And 60 Fonnov Aluminium

When And Why To Use Aluminum 5052 Ryerson

Liczba wierszy 25 · Aluminum is a light metal, about the third of the density of steel, copper,Comparing 6061 and 6063 Aluminum Both 6061 and 6063 aluminum come from the same series, and they, therefore, have the same chemical compositions This factor makes it difficult to distinguish between the two aluminum alloys from a materials properties viewpoint However, it is possible to compare the 6061 and 6063 aluminum alloys based on2 dni temu · The nominal composition of type 6061 aluminum is 979% Al, 06% Si, 10%Mg, 02%Cr, and 028% Cu The density of 6061 aluminum alloy is 27 g/cm 3 ( lb/in 3) 6061 aluminum alloy is heat treatable, easily formed, weldable, and is good at resisting corrosion Mechanical Properties

6061 Vs 7075 Aluminum The Metal Press By Onlinemetals Com

Aluminium Alloy 6061 Exports From India To Dubai Usa Kuwait Saudiarabia Qatar Iran Kazakistan By Ozair Tradelink Issuu

Dhanlaxmi Steel Distributors is one of the leading manufacturers, Supplier and exporters of 6061 Aluminum Plate, ASTM B9 Aluminium 6061 T6 Plates, UNS 6061 Chequered Plate, DIN Sheet, 6061 T6 Aluminium Plates, 6061T6 Plate Suppliers in India1311 · 6061 T6 Extrusions Aluminium alloy 6061 is a medium to high strength heattreatable alloy with a strength higher than 6005A It has very good corrosion resistance and very good weldability although reduced strength in the weld zone It has medium fatigue strength It has good cold formability in the temper T4, but limited formability in T6 temperAluminum 6061 is an extremely versatile heat treatable aluminum alloy due to its content of silicon and magnesium 6061 has a wide range of mechanical and corrosion resistance properties as well as having most of the good qualities of aluminum 6061 is used in a many applications from aircraft structures, yacht construction, truck bodies, bicycle frames to screw machine parts

Friction Stir Welding Of Aluminum 6061 T6 In Presence Of Watercooling Analyzing Mechanical Properties And Residual Stress Distribution Sciencedirect

6061 Aluminum Coil Stock Supplier Slitter Almetals

CHEMICAL COMPOSITION LIMITS1, 2 REGISTERED COMPOSITION—Continued Only composition limits which are identical to those listed herein for a registered designation are applicable to that designation See footnotes on page 18 Registered International Designation OTHERS13 Al · Aluminium 6061T6 is a subcategory of the 6061 aluminium alloy, one of the most widely used aluminium alloy categories in the worldThe alloy is appreciated because of its versatile performance and allaround mechanical propertiesThe "T6" part of the 6061T6 name indicates the type of the tempering treatment process that this aluminium alloy type undergoesZinc no minimum, maximum 025%

Guide To 6061 Aluminum Properties Types Uses Aluminum 6061 Vs 6063 7075 And 24 Dajin Precision

Chemical Composition Of Aluminum Alloy 6061 T6 Download Table

Chemical Composition of 6061 Aluminum This alloy is part of the 6000 series of alloys As such, its major alloying elements are magnesium and silicon Magnesium is added to increase strength, while the silicon is added to reduce the metal's melting temperatureThe forged Aluminium alloy AA 6061 rod hotrolled and annealed was used Table 1 shows the chemical composition of the present 6061 alloy Al alloy was used in the form of ingots The cleaned metal ingots were melted to the desired temperature of 740°C Cover flux was added in to the molten metal in order to minimize theAluminum, Al 958 986 % 958 986 % As remainder Chromium, Cr 004 035 % 004 035 % Copper, Cu 015 040 % 015 040 % Iron, Fe = 070 % = 070 % Magnesium, Mg 080 12 % 080 12 % Manganese, Mn = 015 % = 015 % Other, each = 005 % = 005 % Other, total = 015 % = 015 % Silicon, Si 040 080 % 040 080 % Titanium, Ti = 015 % =

Chemical Composition Of The 1100 And 6061 T6 Wt Download Table

6061 Aluminium Alloy Wikipedia

Al6061 T6 Material Test Report Of Machining Parts

6061 T6 Aluminium Plates Sheets Stockist Suppliers

Typical Composition Of Aluminium Alloy 6061 Download Table

6061 Aluminum Sheet And Plate Supplier With Best Price Tigers Aluminum

Difference Of 6061 T6 6063 T5 Sunshield Aluminum Structures

Http Utw Utweb Utexas Edu Sites Default Files 18 102 selectivelasermeltingofal6061alloyprocessin Pdf

Qrp Now Offering Aluminum 6061 For Additive Manufacturing 3d Printing Media Network The Pulse Of The Am Industry

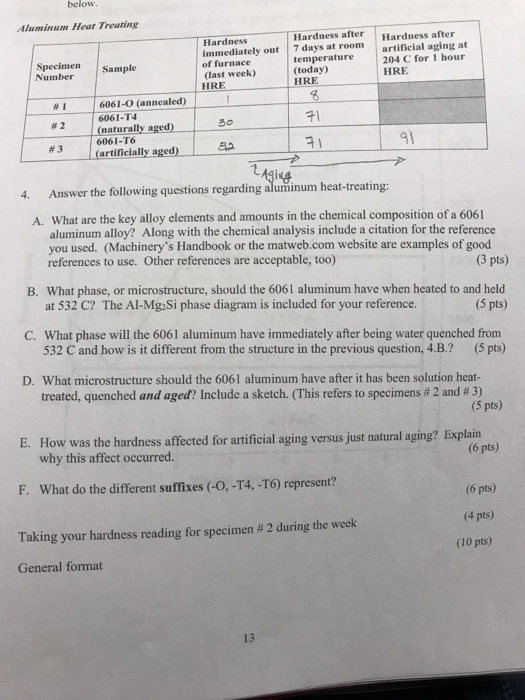

Solved Below Aluminum Heat Treating Hardness Immediately Chegg Com

Which Aluminum Alloy Bends Best Clinton Aluminum

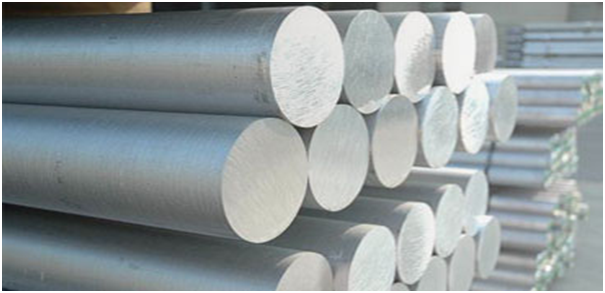

Aluminium Round Bar Aluminum Round 6061 T6 Bar Manufacturer From Mumbai

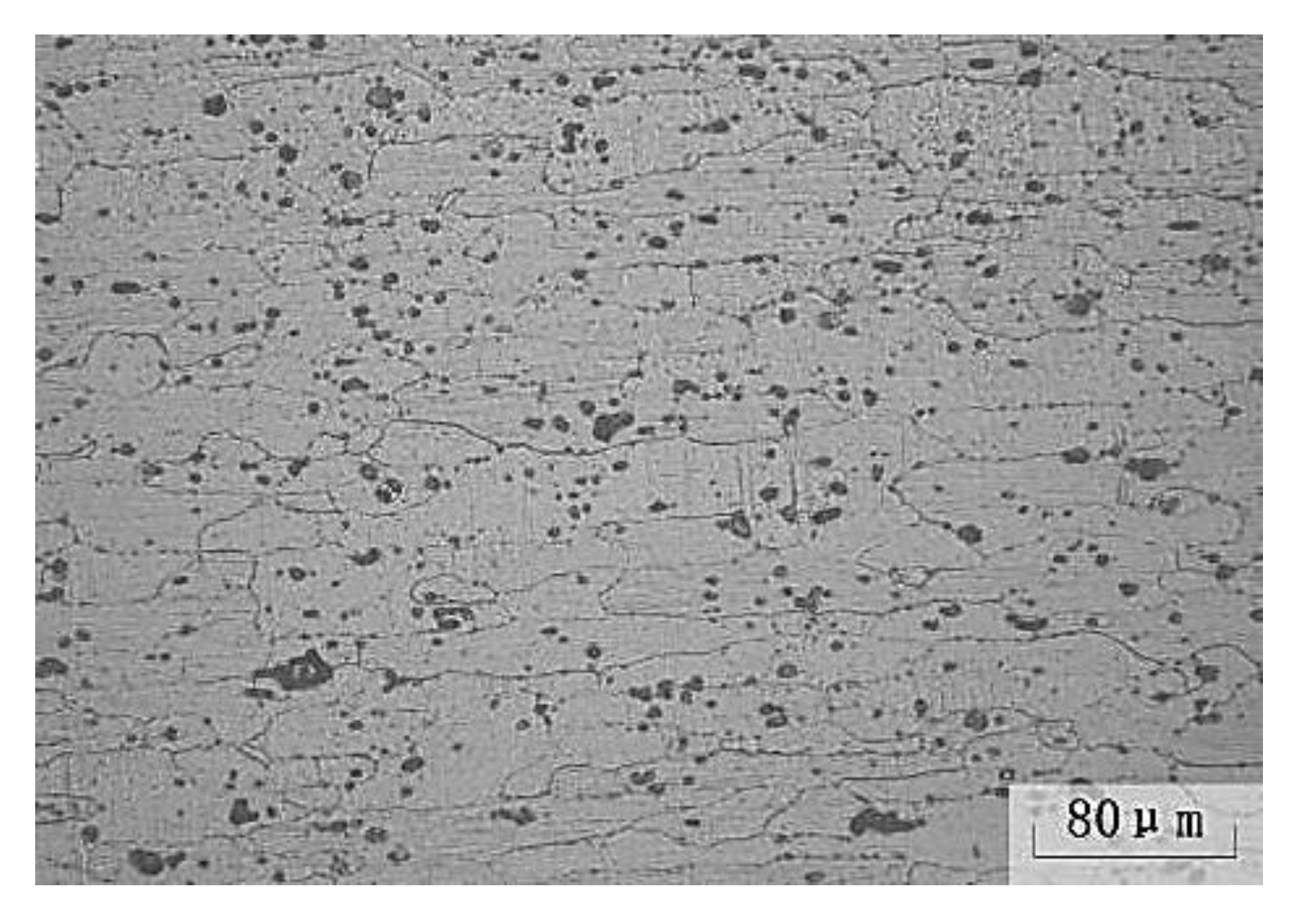

A Comparative Study On The Microstructures And Mechanical Properties Of Al 6061 Alloy And The Mmc Al 6061 Tib Sub 2 Sub 12 Sub P Sub

Aluminium Alloy 6061 Less Price Fast Worldwide Delivery

6061 Aluminum Plate Ams 4027 T6 Temper

Chemical Composition Of Aluminum Alloy 6061 T6 Download Table

High Purity 6061 T6 Billet Aluminum Aluminum Alloy 6061 Ld30 Alsi1mgcu

6061 Vs 7075 Aluminum What Is The Difference Dek

Al 6061 T6 Aluminum Alloy Properties Density Tensile Yield Strength Thermal Conductivity Modulus Of Elasticity Welding

Www Sciencedirect Com Science Article Pii S Pdf Md5 b32a3dc878f2b39dd2aa99 Pid 1 S2 0 S Main Pdf

Scielo Brasil Solution Treatment Behaviors Of 6061 Aluminum Alloy Prepared By Powder Thixoforming Solution Treatment Behaviors Of 6061 Aluminum Alloy Prepared By Powder Thixoforming

Aluminium

Www Upmet Com Sites Default Files Datasheets 6061 Pdf

6061 Aluminum Plate Ams 4027 T6 Temper

Aluminium 6061 T6 Vs Aluminium 6063 T5

Xometry De Wp Content Uploads 09 Datasheet En Aw 6061 Pdf

6061 Aluminum Sheet Suppliers Low Prices For 6061 Aluminium Sheets

Al 6061 Tib Sub 2 Sub Metal Matrix Composite Synthesized With Different Reaction Holding Times By In Situ Method

6061 Aluminum Get To Know Its Properties And Uses Gabrian

1

Pdf Study Of Corrosion Resistance Of Aluminum Alloy 6061 Sic Composites In 3 5 Nacl Solution Semantic Scholar

Typical Composition Of Aluminium Alloy 6061 Download Table

6061 Aluminium Alloy Wikipedia

6061 Aluminum Coil Suppliers Low Prices For 6061 Aluminium Coils

Chemical Composition Of The Aluminium Alloy 6061 Download Table

Chemical Composition Of Al 6061 Alloy Download Table

Wear And Mechanical Properties Of 6061 T6 Aluminum Alloy Surface Hybrid Composites Sic Gr And Sic Al2o3 Fabricated By Friction Stir Processing Sciencedirect

Table 1 From Experimental Investigation Of Aluminium 6061 Alloy By Gas Tungsten Arc Welding Process Semantic Scholar

Metals Free Full Text Research On Laser Tig Hybrid Welding Of 6061 T6 Aluminum Alloys Joint And Post Heat Treatment Html

6061 Aluminum Properties Uses

When And Why To Use Aluminum 6061 Ryerson

5 Aluminum 6061 Chemical Composition Download Table

Wrought Aluminium Alloys By Rahul Issuu

Table 2 From Friction Stir Welding Of Dissimilar Materials Aluminum Al 6061 T 6 To Ultra Low Carbon Steel Semantic Scholar

Chemical Composition Of Aluminium Alloy 6061 Download Table

Aluminium Alloys And Production

6061 Aluminum Bar Rod Block Suppliers Buy Al 6061 Round Flat Bar

Qrp Now Offering Aluminum 6061 For Additive Manufacturing 3d Printing Media Network The Pulse Of The Am Industry

Which Aluminum Alloy Bends Best Clinton Aluminum

Q Tbn And9gcqm Axy Lzszttk31caikxplub0bsgndlwbgqxqk0aiqzldjx0b Usqp Cau

Ena Industry Specifications

Press Brake Bending Applying The Percent Rule To 6061 Aluminum

Pdf Investigation Of Chemical Composition On Widely Used Al 6061 T 6511 Engineered Material An Xrd Analysis Towards Improvement Of Mechanical Properties Semantic Scholar

A380 Aluminum Vs 6061 What S The Difference What Is A380 Aluminum Diecasting Mould

Chemical Composition Is The Determinant Of Aluminium Profile Performances Hoonly Aluminium Profile

Magnesium Alloy Plate Sheet Aluminum 6061 T6 Prices Per Kg

Chemical Composition Of Aluminum Alloy 6061 T6 Download Table

7075 Aluminum Get To Know Its Properties And Uses Gabrian

Chemical Composition Of Al 6061 Alloy Download Table

Chemical Composition And Mechanical Properties Of 6061 T6 Aluminium Download Table

Aluminium Aluminum 6061 Alloy Uns 6061

What Is A356 Aluminum A356 Aluminum Composition Properties Uses A356 Aluminum Vs 6061

Pdf Investigation Of Chemical Composition On Widely Used Al 6061 T 6511 Engineered Material An Xrd Analysis Towards Improvement Of Mechanical Properties Semantic Scholar

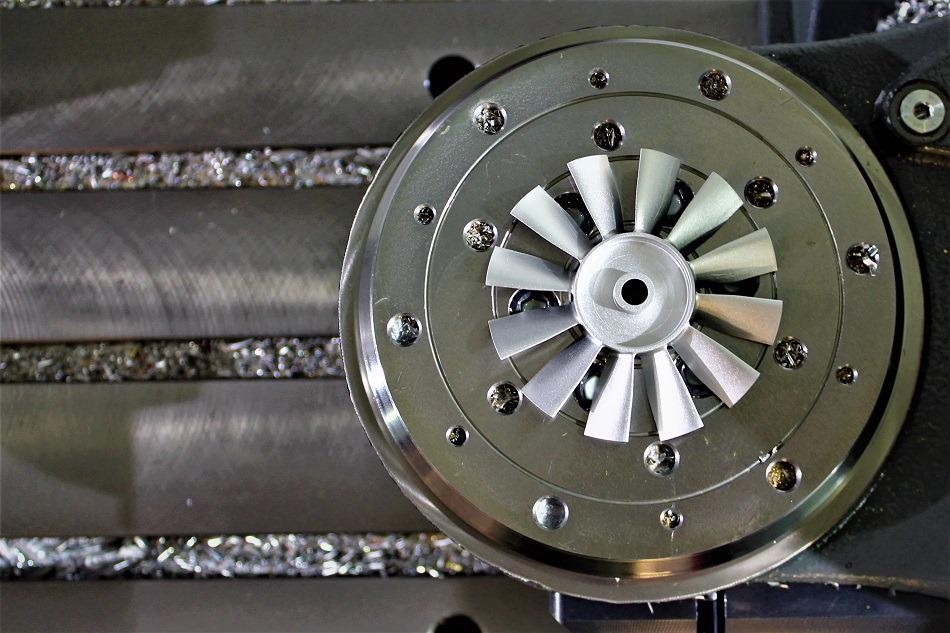

Extrusion Process

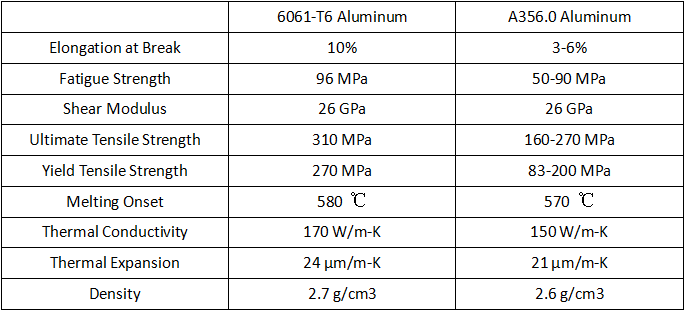

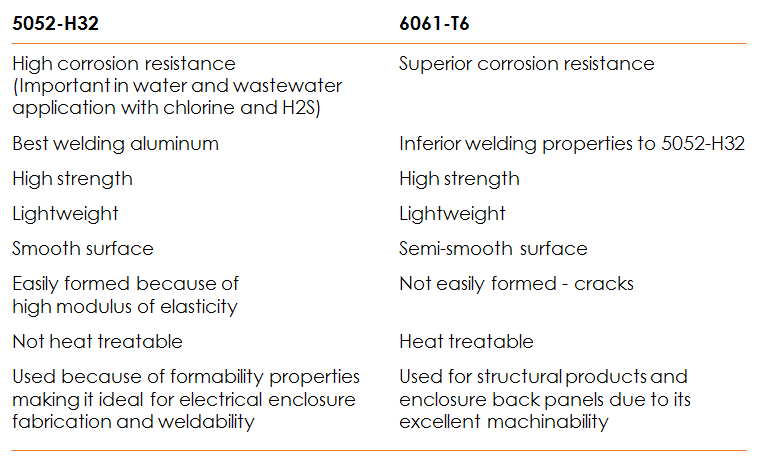

5052 Vs 6061 Aluminum Properties Yield Strength Differences Of 5052 H32 Vs 6061 T6 Nema Enclosures

Alloy 6061 Aluminum Based Precipitation Hardened

Astm 08 08m 02 Standard Specification For Aluminum Alloy 6061 T6 Standard Structural Profiles

Aluminium Alloy 6061 Aluminium Guide Com

China Factoty High Quality Professional Aluminum 6061 Seamless Pipe Tube China 6061 Aluminum Tube 6061 T6 Aluminum Pipe Made In China Com

Chemical Composition Of Aluminium Alloy 6061 Download Table

6061 Aluminum Get To Know Its Properties And Uses Gabrian

1

Which Aluminum Alloy Bends Best Clinton Aluminum

Aluminum Machining Composition Tempers Applications

Chemical Composition And Mechanical Properties Of 6061 T6 Aluminium Download Table

Effect Of Homogenization Temperature On The Microstructure And Property Of 6061 Aluminum Alloy With Erbium Scientific Net

Aluminium Alloy 6061 Aluminium Guide Com

Table 1 From Solid State Recycling Of Aluminum Alloy 6061 Chips Via Hot Extrusion Followed By Equal Channel Angular Pressing Ecap Semantic Scholar

Aluminium Alloys And Production

6061 Aluminum Rectangle Square Tube Pipe

コメント

コメントを投稿